P-CVD

- P-CVD Notice: Undefined offset: 2 in /home/host/cvdvalve/www/html/_skin/layout/inc_navigation_middle.php on line 60 Notice: Undefined offset: 2 in /home/host/cvdvalve/www/html/_skin/layout/inc_navigation_middle.php on line 86 Notice: Undefined offset: 3 in /home/host/cvdvalve/www/html/_skin/layout/inc_navigation_middle.php on line 86

P-CVD TREATMENT (PENETRATED CVD)

- HRC80(HV1800-2000)

What is P-CVD?

CVD is defined as ‘a surface hardening by thermochemical diffusion penetration’ and it greatly increase wear-resistance, corrosion-resistance & thermal resistance. This is not a simple coating on the material surface, but a surface penetration with CVD method. So, the P-CVD treated material has no flaking which usually takes place in the general coated material such as stellite coating, tungsten carbide coating, chrome carbide coating and so on.

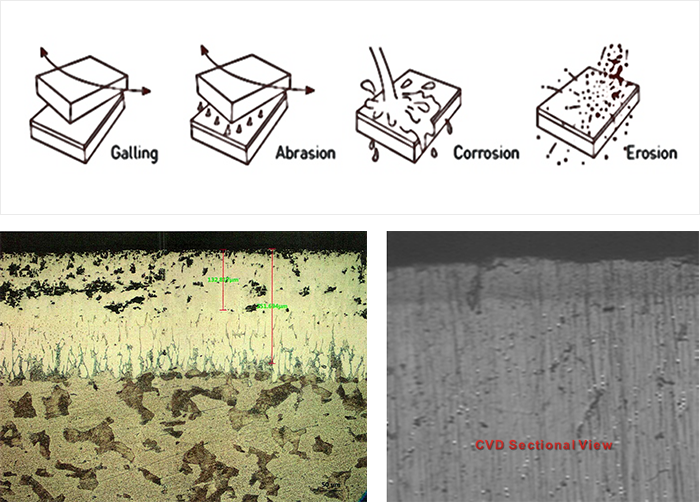

Superior in Galling, Abrasion, Erosion

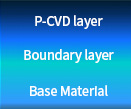

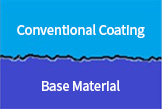

Comparisons between P-CVD and Conventional Coating

| Type | Our P-CVD™ | Conventional Coating (HVOF) | ||

|---|---|---|---|---|

| Stellite #6 | Tungsten Carbide | Chrome Carbide | ||

| Structure |

High quality similar boundary layer is formed

between CVD layer & base material. Thus there is no flaking effect due to strong coherence. High quality similar boundary layer is formed

between CVD layer & base material. Thus there is no flaking effect due to strong coherence.

|

It is clearly divided between CVD layer & base material. Thus there is a flaking effect. It is clearly divided between CVD layer & base material. Thus there is a flaking effect.

|

||

| Structure |

Become shiny more when we use it. Become shiny more when we use it.

|

As we use it, there are flaking, abrasion and

corrosion generated. As we use it, there are flaking, abrasion and

corrosion generated.

|

||

| Application | Valves, Pumps for polysilicon, oil refinery, petrochemical, mining, steel and iron plant, instead of conventional coating such as tungsten, chrome carbide, stellite coating | Low graded Valves for gentle slurry and solids in petrochemical, steel and iron plant etc. | ||